SEAC patents polymer headed fasteners

1st June 1981

Registered Polytops trademark. Made Polytops pins, nails, screws & rivets in Zinc Plated Steel for internal caravan use.

Demand for application outdoors

1st May 1984

PVC fascia, soffit & cladding. Added A2 Stainless Steel option for corrosion resistance.

Coastal area corrosion

2nd December 1990

Feedback from application near coast that after 2 years, the A2 Stainless Steel nails had corrosion.

Upgrade to A4 Stainless Steel

5th August 1991

Upgraded A2 to A4 Stainless Steel. Passed all corrosion test. No corrosion complaints ever received.

SEAC commissions Salt Spray Test

18th March 2014

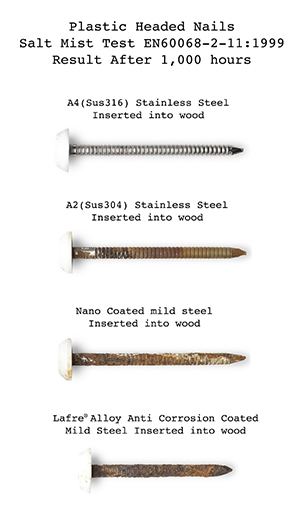

Studied alternative forms of fastener – Nano Coating Corrosion tests on all types of nails done by UCAS accredited lab. All corroded badly except A4 Stainless Steel nails.

Attained CE Mark EN14592

15th April 2015

Attained CE Mark EN14592 for Polytops pins (25, 30, 40mm) and nails (40, 50, 65mm)

The detailed POLYTOPS® Story

SEAC have been manufacturing POLYTOPS® polymer colour headed pins and nails for over 40 years.

POLYTOPS® were first used for fixing internal trims in static mobile homes and caravans. The pins and nails were then made of zinc plated mild steel with moulded plastic head in various colours. It was well suited for this internal application.

However, within 1 to 2 years of the fitting, zinc plated mild steel nails and pins did not have the level of corrosion resistance required. The result was rust stains and marks appearing peoples uPVC fascia and soffit boards. This was most prevalent in coastal and industrial city areas where the environment was moist harsh. In consultation with the major fascia and soffit board manufacturers we made the decision to upgrade our nails and pins material from zinc plated mild steel to A2 (SUS304) stainless steel. This is an austenitic stainless steel with improved corrosion resistance due mainly to the addition of Chrome (17.5% – 19.5%) and Nickel (8% – 10%).

Unfortunately problems began appearing with this A2 stainless steel material, with the same rust-like brown stains on the fascia and soffit boards. This was particularly notable in coastal regions. So after another review we swiftly remedied this issue by upgrading the steel again. This time to A4 (SUS316) stainless steel.

The grade of steel has an increased nickel content (10% – 13%) and the addition of molybdenum (2%) further increased the corrosion resistance. This material is commonly referred to as “Marine Grade Stainless Steel”. We introduced the A4 marine grade stainless steel to our POLYTOPS® plastic colour topped nails and pins, around 1991. From this date we have had no staining or rust issues and therefore only recommended A4 stainless steel in and nails and pins that are used for outside use, in particular with the fitting of fascias and soffits.

POLYTOPS® Story – Salt spray test

Over the years we have tests the steels to make sure we are using the correct material for the application. In 2014 we conducted a salt spray test. It was carried out by an independent UKAS accredited laboratory, to British (and then European) Standards. The test was designed to simulate the products in actual use.

The test was to simulate the product in actual use. The nails tested were finished products taken out of an unopened random box of nails and hammered into wood, as it wood be if fitted to a fascia board.

The A4 nail shows no deterioration, unlike all the other types of nails. This is why we only supply our POLYTOPS® plastic colour topped nails and pins in the A4 marine grade stainless steel. It also why we say to all professionals manufacturers of UPVC fascia profiles, distributors and installers to only use A4 marine grade stainless steel nails and pins to avoid unnecessary damage and repairs to to fitted fascia, soffits barge boards and trim fittings.

Summary

In summary to our POLYTOPS® Story I am sure you appreciate the value of the quality and minimising your risk of having your expensive fascia fitting from the avoidable staining that can happened if the wrong fixing has been used.

For the sake of a few pounds don’t risk using anything other than POLYTOPS® A4 (SUS316) marine grade stainless steel Nails and Pins for the fitting of fascia and soffits

Contact us to find our more